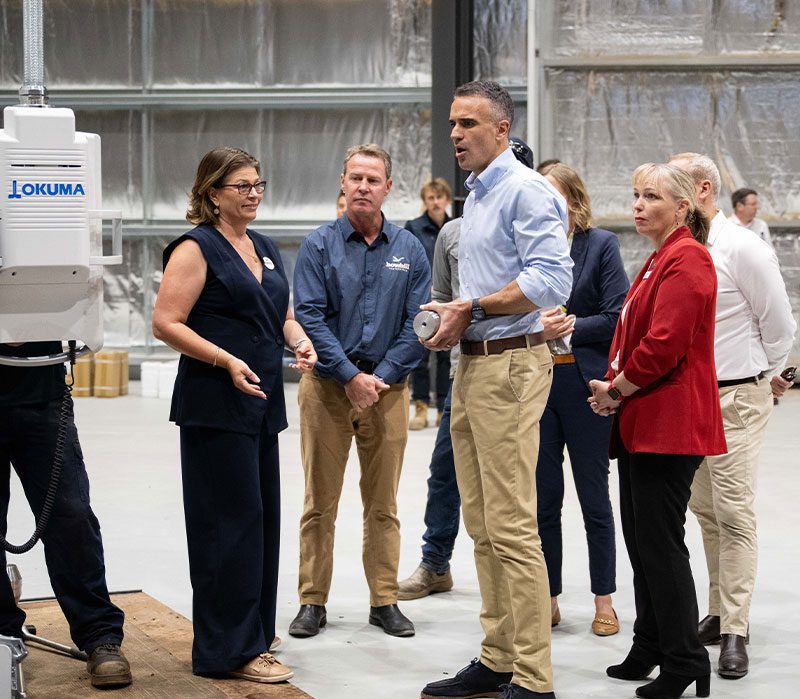

Friday, 6th February 2026, marked a significant milestone for Bowhill Engineering.

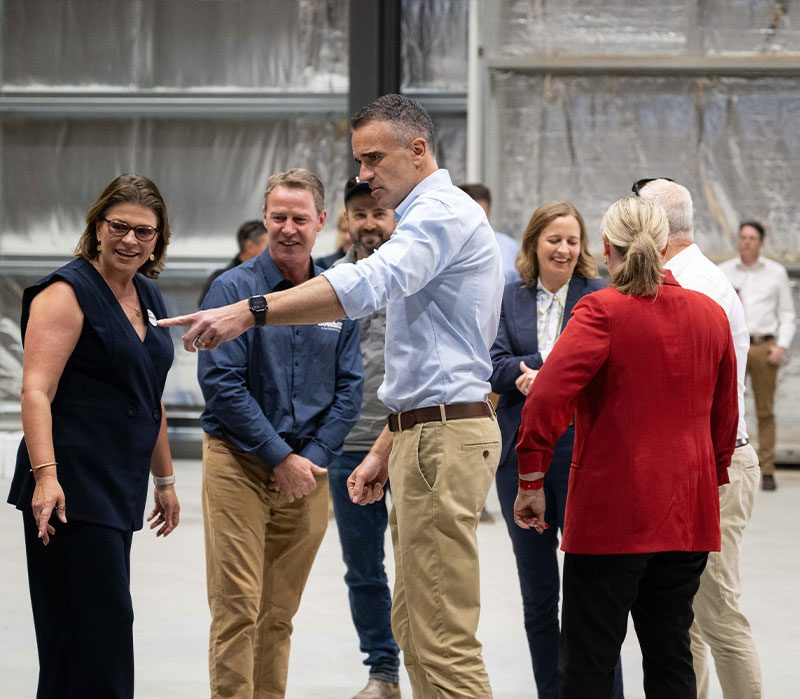

We opened our doors to showcase our new facilities and advanced manufacturing capabilities to industry partners, government representatives, and our regional community.

The day was about more than new equipment. It was about why we’ve invested in it, what it means for our team, and how it positions regional South Australia manufacturing for the future.

More Capability. More Impact.

As CEO, Jodie Hawkes shared in her opening address, this day mattered to us – not because we’ve bought new equipment, but because of why we’ve invested in it.

“Over the past few years, we’ve been very deliberate about the kind of business we’re building here at Bowhill,” Jodie explained. “One that can take on complex work, deliver safely and consistently, and create real opportunities for people in regional South Australia.”

What We Unveiled

Guests stepped inside our new B5 workshop and upgraded B2.2 building to see four major pieces of equipment now in operation.

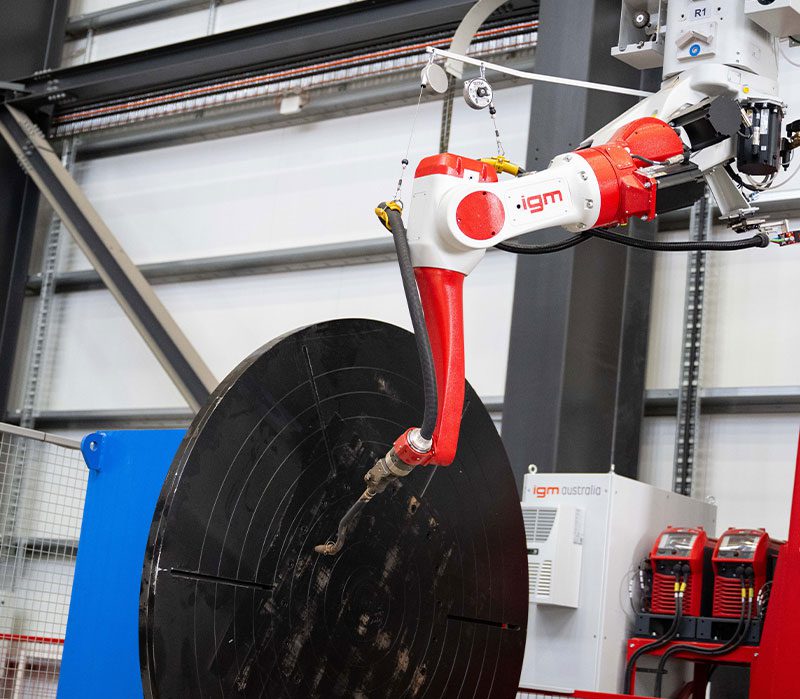

New B5 Workshop – Three state-of-the-art robotic welding systems supporting our structural steel fabrication capabilities for major infrastructure projects.

Upgraded B2.2 Building – Advanced CNC Machining Centre enhancing precision metal fabrication and complex component manufacturing.

Jeremy Hawkes, Director of Business Development, led guests through the equipment unveiling and facility tours. As Jodie introduced him: “To take us through the unveiling, is my partner in crime, we’ve been together since we were 15 and have worked together for 23 years, he’s the father of our 4 great kids…”

This personal touch reflects how Bowhill Engineering operates – as a family business that’s grown into a regional manufacturing leader while maintaining strong community connections.

Why These Systems Have Names

Each piece of equipment was formally named during the ceremony and that’s intentional.

“Behind every piece of technology are the people who operate it, maintain it, design around it, and depend on it to get home safely at the end of the day,” Jodie said.

The robotic systems and CNC machining centre aren’t about replacing people. They’re about backing our people giving them the tools, precision, and scale to do work that simply wasn’t possible at this capacity before.

Strengthening Major Projects Delivery

This capability strengthens how we deliver major projects, including the Torrens to Darlington Project, and positions Bowhill Engineering as a long-term partner for complex infrastructure, not just now, but well into the future.

Our investment directly supports:

Real Jobs, Real Skills, Real Impact

This investment is about real jobs, real skills, and real impact for our workforce, our partners, and the communities we’re all part of. Currently employing 67 people, including 15 apprentices across metal fabrication, boilermaking, welding, and engineering roles, we’re committed to:

Want to be part of our next chapter? Visit boweng.com.au/our-vacancies to explore apprenticeship and career opportunities at Bowhill Engineering.

The Impact Ahead

We’re proud of what’s been built, and we’re even more excited about what it enables. From major infrastructure projects like the Torrens to Darlington to supporting local industry needs, our enhanced capabilities position Bowhill Engineering to deliver complex structural steel work for decades to come.

Thank you to everyone who attended our Open Day, to our special guests for their support, and to our entire team who made this investment possible – Together, we thrive.